KES Group’s industrial wood boards are made of natural wood fiber with realistic 3D grain designs to create the feeling of bringing nature into the living space.

KES Group is one of the largest industrial wood manufacturers in Vietnam with a high supply capacity from 5 wood production factories with an area of nearly 1.2 million m2, equipped with modern machinery systems. The Company's product portfolio is very diverse such as melamine-faced MDF, and laminate to raw boards such as MDF, HDF, LMR. In addition, the Company also provides laminate flooring and other additional products such as wooden edges, borders, and braces.

“Our Company can meet large orders with a production capacity of up to 1 million m3 a year for MDF products and 10 million m2 a year for melamine-faced MDF and laminate flooring,” the Company’s representative shared.

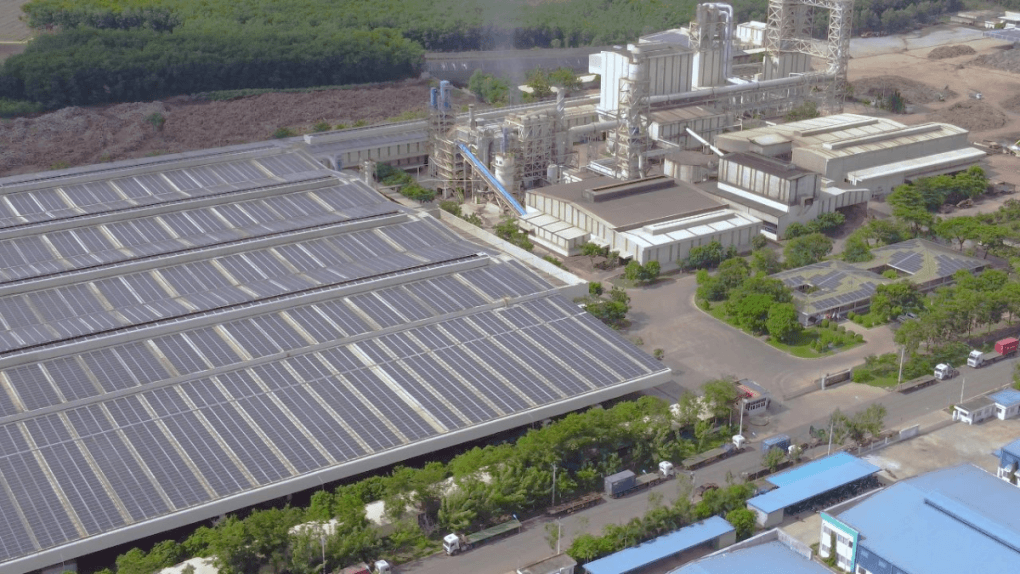

An industrial board production factory of KES in Binh Phuoc Province

The Company is not only oriented as a high-end industrial wood panel brand but also as a green visioner who is committed to sustainable development in all operations. Acknowledging the limitations of natural wood supply sources as well as the environmental impacts of industrial production processes, the Company has developed a closed production process chain, controlling from input materials to finished products. Throughout this process, the Company’s green vision is built in three aspects.

Firstly, the Company commits to using natural wood fibers as raw materials, and actively researches and develops future reforestation projects to protect the natural ecosystem. Secondly, the Company invests in advanced machinery and technology systems from Germany and Switzerland with highly automated production lines. This not only helps optimize the capacity and product quality but also strictly controls the emission index, ensuring low formaldehyde content and meeting safety standards. Moreover, KES Group’s factories prioritize using environmentally friendly solar energy in all their production activities. Thirdly, KES Group focuses on staff training, ensuring that each employee understands and implements sustainable principles and processes.

The Company’s target of connecting people with natural inspiration is also clearly expressed through the product journey “From forest to living space - bringing green forests into the living space”. Originating from the forest with natural wood fibers, board cores of KES Group's factories are formed after wood chips go through a system of steaming, crushing, spraying, mixing, pressing, and sanding.

KES communicates the message “Bring green forests into living space” on the occasion of the brand’S launch at Vietbuild 2023

Inspired by the beauty of nature through wood grains, the Company continues to create decorative panels using a synchronous 3D grain printing system, creating a beautiful coat for wooden panels. Decorative panels are then covered with high-quality core boards, creating high-quality wooden panel products, which are brought to stores and become the choice for those who want to create a luxurious, sustainable, and accessible living space close to nature.

Sharing more about the advantages of industrial wood products of KES Group, the representative said that the durable core boards are the first that come to mind. The board density is from 810 - 830 kg per m3 and natural wood fiber, products will generate a solid foundation for the living space.

Next is the surface layer. With 3D grain, wooden boards provide a realistic feeling, like bringing nature into the living space. The Brand also offers a variety of pattern options with more than 600 color codes, and many types of grain such as oak, maple, walnut wood, stone motifs, and fabrics, etc. This provides many options that are suitable for each project’s design.

KES Group’s industrial wood boards are highly appreciated for their safety for health. The product lines are certified to contain low formaldehyde contents and are not harmful to health as they meet the US Carb P2-EPA emission standards.

Wood material appears in many modern living spaces

Wood has long been the favorite material of many people when designing interiors because its natural beauty which brings a peaceful, close-to-nature feeling to living space.

Many data show that the demand for wooden furniture in the Vietnamese market is significant. Statistics by the General Statistics Office of Vietnam show that in recent years, an average of about 96 million m2 of houses are constructed each year in Vietnam, generating great demand for interior wood used for floors, cabinets, tables, chairs, etc.

In foreign markets, although the wood industry is still facing many challenges due to the general impact of global fluctuations, data from the General Statistics Office also show positive signs. In the first 4 months of the year, the export value of wood and wood products has changed positively after each month, increasing from 806 million USD in January to 875 million USD in February; up to 1.1 billion USD in March and maintained at 1.1 billion USD in April.

Based on the opinion of the Vietnam Timber and Forest Product Association (VIFOREST) “In the second half of the year, expectations for wood and wood product exportation are more positive as economies improve and the tourism industry recovers, thus demands for furniture replacement of restaurants and hotels will increase. At the same time, the recovery of construction activities will boost demand for furniture”.

Although the demand is high, wood resources are limited. If natural wood exploitation is not controlled, it can negatively impact the environment, causing serious consequences such as storms, floods, etc. “Therefore, industrial wood is being promoted as a potential solution to reduce pressure on natural forest resources while still satisfying consumer needs by creating green living spaces from wood,” the Company’s representative shared.